Well, had a setback already this month, as it seems the company I tried ordering some replacement rollers from was fraudulent. After placing my order for two SynTac 12069 Upper Pullout Rollers on November 3, I didn’t immediately receive an order confirmation and so I wrote to ask about it. My email was forwarded to a third party who told me the order has already been shipped and to wait patiently. Okay, thanks.

Weeks later and still no package, I tried writing them again to try to get a tracking number so I could verify the shipment, but received no response at all from those emails. So, after a solid 30 days I submitted my refund request through Paypal. At least that part was painless, the money is already back in my account. But now I’m left looking for another supplier. These rollers aren’t being manufactured anymore, and so are becoming harder to source. I can find them on ebay for $80-90 apiece, which is a lot more than the $25 each I had paid the unresponsive seller. I think I found another reputable seller with a more manageable price, but I have to wait until I get paid again in another week to try to place that order.

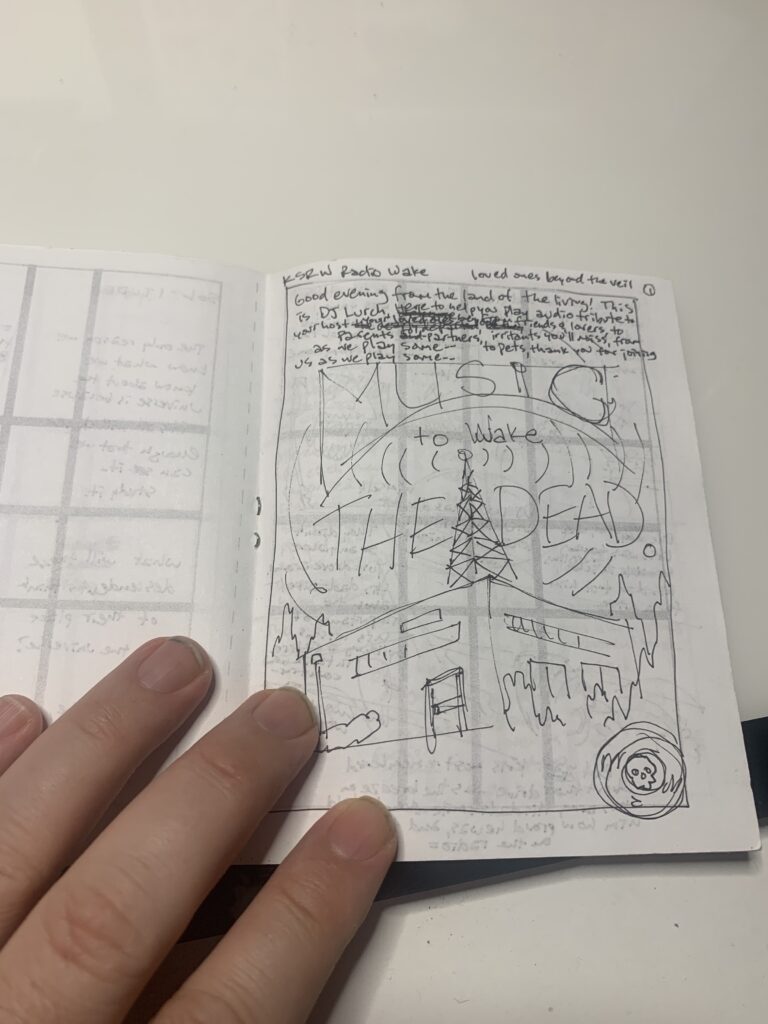

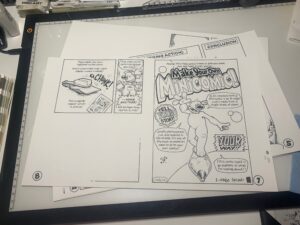

In the meantime, I’m going to go ahead and re-install the seriously worn-out rollers I already have, and start trying out some test printing this next week. I’ve got a lot of projects piled up, waiting to have plates burned and get printed, and I’d love to start checking those off this month! Stay tuned!